Rebuilt Transmissions: A Practical Guide to What They Are and Key Benefits

Outline and Why Rebuilt Transmissions Matter

Replacing a failing transmission is one of the weightier decisions a vehicle owner faces. The choice affects safety, long‑term ownership costs, and how reliably your car or truck gets you where you need to go. Rebuilt transmissions offer an appealing middle ground between installing a factory-new unit and gambling on a used one with an unknown past. This guide lays out what “rebuilt” truly means, how the process is performed, the advantages that matter in real life, and what to check before committing. Think of it as a map: clear signposts, practical details, and a few seasoned tips so you can navigate with confidence.

Here’s the roadmap we’ll follow so you always know what’s next:

– What Are Rebuilt Transmissions? Definitions, how they differ from repaired, used, and remanufactured units, and when each option makes sense.

– Inside the Rebuild: A step‑by‑step look at teardown, inspection, component replacement, assembly practices, and testing.

– Benefits You Can Feel: Cost control, reliability, updated parts, and sustainability compared with other routes.

– Choosing and Budgeting: How to evaluate shops, understand estimates, compare warranties, and avoid common pitfalls.

– Final Guidance: A concise decision framework to match your budget, timeline, and vehicle plans.

Why does this matter now? Automatic and modern dual‑clutch or CVT systems are complex assemblies with tight tolerances and electronics that must play nicely together. When they fail, the symptoms—slipping gears, harsh shifts, delayed engagement, burnt fluid—can quickly escalate. A thoughtful rebuild addresses not just the obvious failure, but underlying causes such as worn bushings, tired solenoids, or outdated valve body calibrations. Well-executed work can restore smooth, consistent shifting and give an aging vehicle a second chapter. The goal of this article is to make a complex topic accessible, provide grounded comparisons, and help you decide whether a rebuild aligns with your plans for mileage, ownership length, and overall budget.

What Are Rebuilt Transmissions?

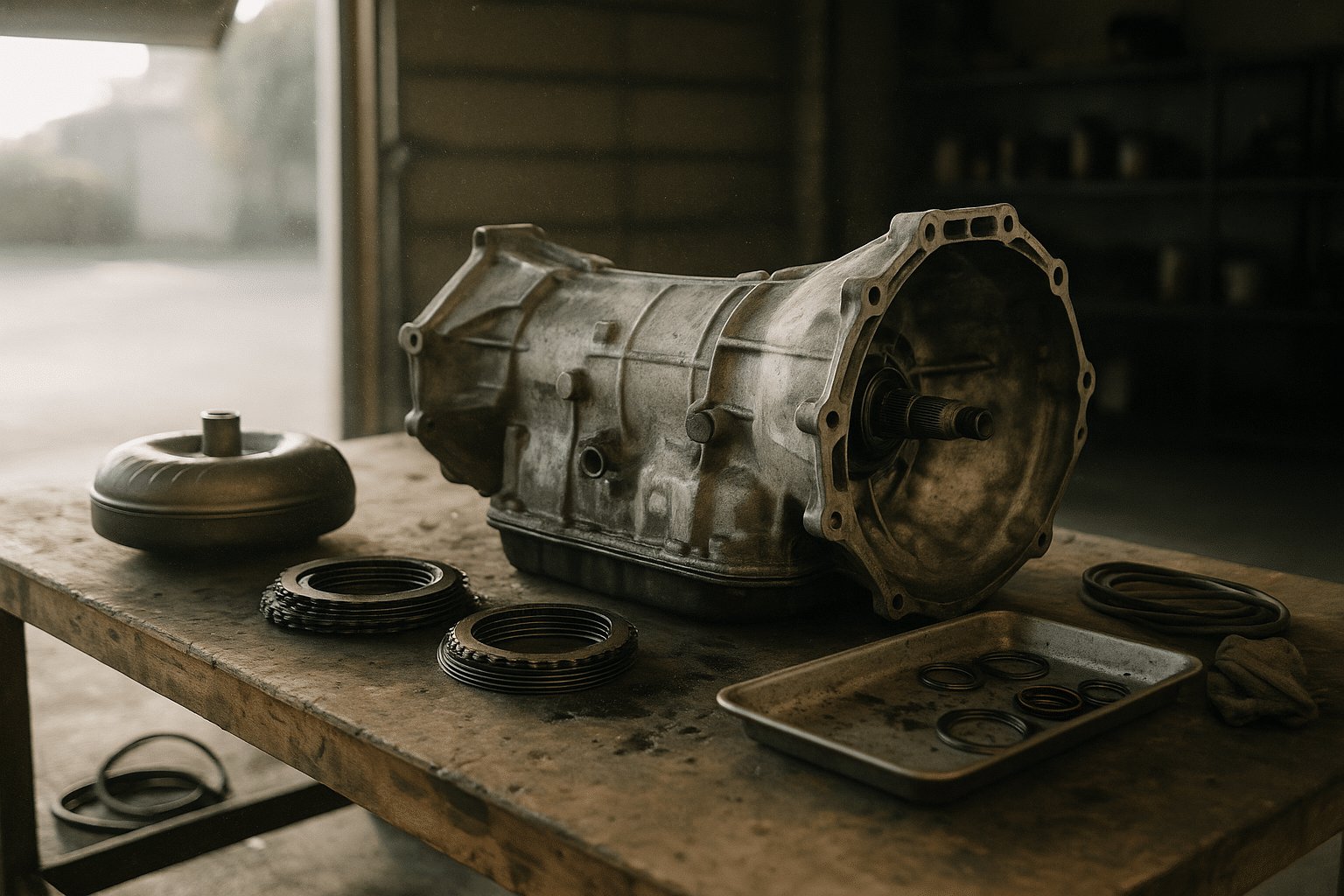

A rebuilt transmission is a used unit disassembled and reconditioned so that worn, damaged, or failure-prone components are replaced and the assembly is restored to serviceable condition. At its core, rebuilding is about resetting the internal health of the system. The process typically includes new friction materials (clutch packs and bands), seals and gaskets, and any hard parts—gears, drums, sprags, bushings, or valve body components—that fail inspection. Electronics such as solenoids, pressure switches, and sensors are tested and replaced as needed. The torque converter is either replaced or rebuilt to ensure proper lockup and fluid coupling. Finally, the unit is reassembled to spec and tested.

It helps to distinguish a rebuilt transmission from neighboring options:

– Repair: Targets a specific issue (for example, a failed solenoid or a leaking seal) without comprehensive teardown. It can be cost-effective for minor faults but may not address hidden wear.

– Used (Salvage): A previously running unit installed as-is with fluid and filter service. Pricing can be attractive, but internal condition and remaining life are unknown variables.

– Remanufactured: A more standardized, factory-like process with set replacement lists and rigorous test procedures applied to each unit. It often commands a higher price and can include broader warranty coverage.

– New: A unit assembled from new components. It’s usually the highest-cost path and less common for older vehicles.

So when does “rebuilt” make sense? It’s a strong candidate when the vehicle is otherwise sound, you plan to keep it for several years, and you want a balance between cost and reliability. Consider an example: a family SUV with 150,000 miles begins to flare between shifts and displays a transmission overheat warning. A diagnostic scan reveals clutch slippage and a valve body pressure irregularity. Rebuilding allows a technician to replace friction materials, address valve body wear, update calibration where applicable, and ensure the torque converter locks properly—all while inspecting for collateral damage. The result is a refreshed powertrain component tailored to the specific failure pattern your unit displayed.

The value of rebuilding lies in targeting both cause and symptom. Rather than swap in a mystery component or fix one leaky seal, a rebuild establishes a renewed baseline—fresh hydraulics, proper clearances, tested electronics—that supports consistent, predictable shifts.

Inside the Rebuild: Process, Parts, and Quality Standards

While shops vary in tooling and house standards, thorough rebuilds share a core sequence. Understanding that sequence helps you evaluate an estimate and ask the right questions. Think of it as taking a mechanical orchestra apart, tuning each instrument, and reassembling it so the score plays cleanly again.

The step-by-step arc usually looks like this:

– Verification and Diagnostics: Fluid is checked for burnt smell, debris, or metallic glitter. A scan tool reads fault codes and live data like line pressure and shift timing. Road testing reproduces symptoms.

– Removal and Teardown: The transmission is removed from the vehicle, drained, and stripped on a clean bench. Subassemblies—pump, gearsets, drums, valve body—are laid out in order.

– Cleaning: Cases and parts go through solvent or aqueous wash, then compressed air drying. Passages are brushed; stubborn varnish is removed so hydraulic circuits are clear.

– Inspection and Measurement: Components are measured against specifications—clearances, runout, spring tension. Anything out of tolerance is replaced.

– Replacement of Wear Items: New clutches, steels, bands, bushings, bearings, seals, and gaskets are installed. Known failure-prone parts for that model are proactively updated.

– Valve Body and Electronics: Spool valves are checked for scoring; bores may be sleeved; solenoids are tested and replaced if weak or sticking.

– Torque Converter Service: Either replaced with a quality unit or rebuilt with new internals and lockup clutch.

– Assembly and Setup: Clearances are set with selective shims; fasteners are torqued; endplay is verified; pan is fitted with a fresh filter.

– Testing: Hydraulic pressure is tested on a bench; then the unit goes back in the vehicle for fluid fill, adaptation resets, and road testing under different loads.

Quality standards you can look for include documented torque specs, measured endplay, test sheets with pressures and temperatures, and a list of replaced components. Ask whether the shop incorporates updated parts or design revisions that address known vulnerabilities for your transmission model. For example, certain units benefit from improved valves to reduce cross‑leakage, upgraded clutch materials for heat resistance, or revised bushings to combat premature wear. These incremental upgrades can make a tangible difference in shift quality and lifespan.

Finally, fluid choice and break‑in matter. Using the correct specification fluid is essential for friction and hydraulic behavior. After installation, a proper drive cycle allows control modules to relearn shift timing. A follow‑up inspection for leaks and fluid level checks helps catch early issues. When these details line up, the rebuilt unit behaves not just like it works—but like it belongs.

Benefits of Rebuilt Transmissions: Cost, Reliability, and Sustainability

Owners choose rebuilt transmissions for a handful of practical reasons that often add up to real-world value. The first is cost control. A rebuild commonly lands between a used unit’s low entry price and a remanufactured unit’s premium, reflecting the labor and parts invested. Exact numbers vary by vehicle, transmission type, and region, but many drivers see quotes that compare roughly as follows:

– Used (installed): Often the lowest initial cost, but condition is uncertain and warranties are typically limited in scope or duration.

– Rebuilt (installed): Moderately priced, with the advantage of replaced wear items, verified clearances, and testing tailored to your unit.

– Remanufactured (installed): Higher price, standardized parts lists, and broader test protocols; sometimes accompanied by longer warranties.

– New (installed): Highest price, less common for older models, usually chosen when downtime and risk tolerance demand a new assembly.

Reliability is the second pillar. Because a rebuild involves inspection and replacement of worn parts, it addresses root causes that a repair might miss and a used swap cannot guarantee. Updated friction materials, renewed seals, and calibrated valve body functions translate to more consistent shifts and fewer surprises. Many shops back their work with mileage and time coverage—commonly ranging from around 12 months/12,000 miles to 36 months/36,000 miles, depending on the level of service and intended use. The key is to read the terms: is it nationwide or local, parts only or parts and labor, prorated or full replacement?

Third, there’s a quiet sustainability win. Rebuilding keeps the bulk of the housing and many serviceable hard parts in use, reducing the demand for new raw materials and the energy tied to manufacturing. For owners who want to maintain a vehicle rather than replace it at the first major failure, a rebuild supports responsible resource use while still delivering functional reliability. Add in better shift feel and the option to integrate design updates, and the case strengthens further.

Finally, availability and turnaround can favor a rebuild. In markets where remanufactured or new units are back‑ordered, a skilled rebuilder can often return your original transmission to service on a predictable timeline. That means less time off the road and fewer towing or rental costs. When tallied together—measured spending, renewed internals, and credible warranty support—the advantages form a balanced package for daily drivers, work vehicles, and family haulers alike.

Choosing, Budgeting, and Final Guidance

Selecting a shop and understanding the quote are as important as the technical steps. Start by verifying experience with your specific transmission family, because design quirks and updates are model‑dependent. Look for facilities that provide written estimates, clear parts lists, and test documentation. A quick phone call can reveal how they communicate and whether they stand behind the work.

Questions worth asking before you approve the job:

– What components are automatically replaced, and which are replaced only if out of spec?

– Is the torque converter replaced or rebuilt, and how is its lockup function verified?

– How are the valve body and solenoids tested, and are updated parts used for known issues?

– What are the warranty terms, and what actions could void coverage?

– How is fluid spec determined, and are adaptation procedures performed after install?

Budgeting goes beyond the headline number. A thorough estimate should itemize labor hours for removal/installation, teardown and assembly, parts kits (frictions, steels, seals), hard parts that may be variable, torque converter service, fluid, filter, and shop supplies. Expect variability for hard parts because inspection findings differ from unit to unit. Build in contingency funds for unexpected discoveries such as cracked drums or worn gearsets—items that are impossible to confirm until the case is open.

Practical ownership tips after the job include gentle driving during the initial adaptation period, monitoring for seepage, and checking fluid level and color at the first follow‑up. If your vehicle uses a transmission cooler in the radiator or an auxiliary cooler, ensure it is flushed or replaced to prevent contamination. For vehicles with software‑controlled shifting, request that adaptations be reset and, where applicable, that calibration updates be applied to harmonize hardware and software behavior.

Conclusion for everyday drivers: If your vehicle is structurally sound and fits your life for the next few years, a properly rebuilt transmission can be a financially sensible, technically robust choice. It aligns cost with care, refreshes the parts that actually wear, and gives you transparent documentation of what was done. By choosing a shop that measures, tests, and communicates, you reduce uncertainty and extend the useful life of a major component. That’s the kind of quiet win that keeps road trips predictable, commutes uneventful, and budgets on track.