Prefabricated Capsule Rooms: A Practical Guide to Modular Micro-Living

Introduction and Outline

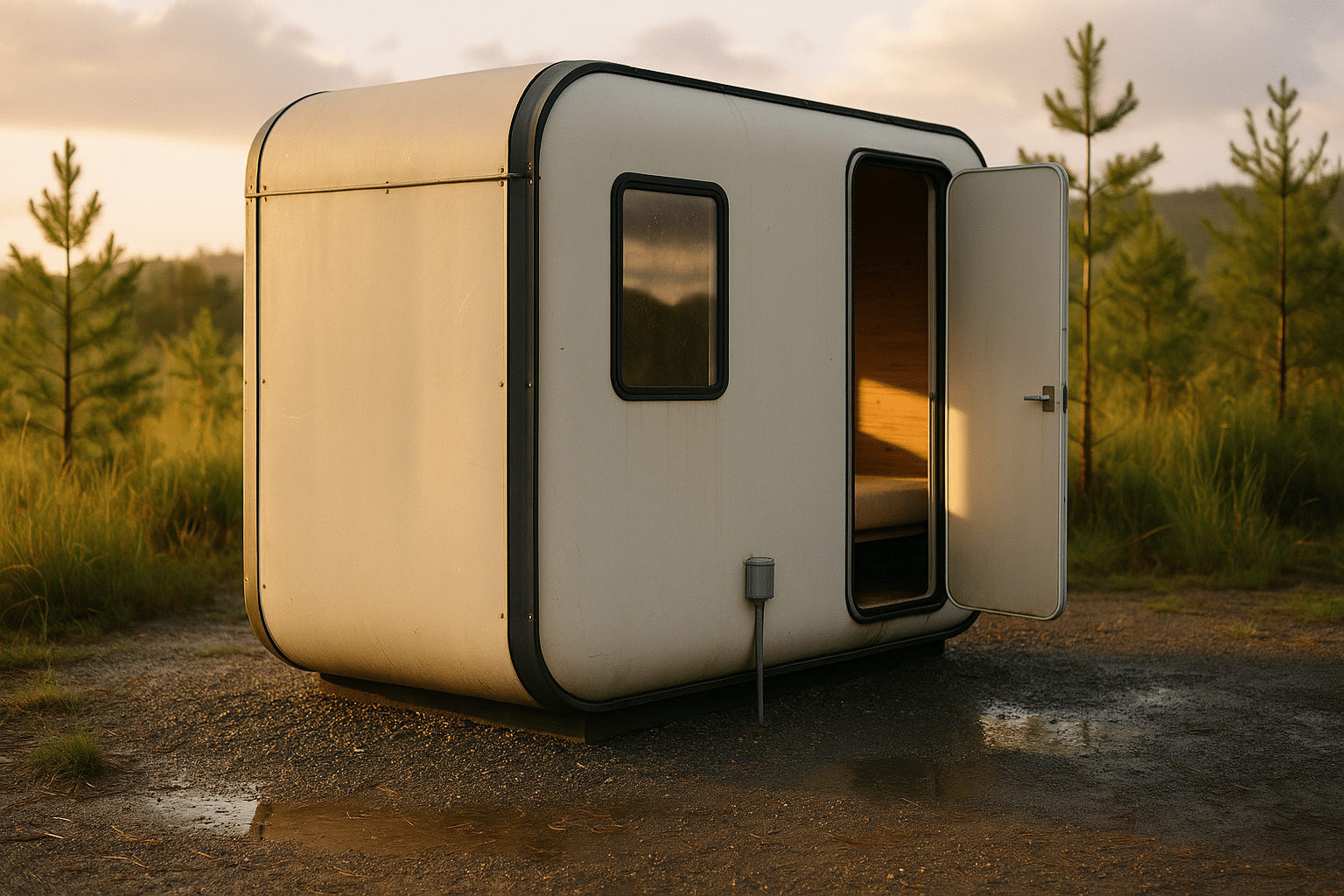

Prefabricated capsule rooms are compact, factory-built modules designed to provide essential living functions in a minimal footprint. They arrive largely finished, connect quickly to services, and transform underused corners—backyards, rooftops, parking lots—into purposeful space. As cities densify and construction costs pressure budgets, capsules offer a nimble alternative: predictable quality, short timelines, and flexible deployment for student housing, short-stay hospitality, workforce accommodation, and personal studios. Think of them as the building world’s version of carry-on luggage—small, efficient, and enough for the essentials when you plan wisely.

This guide is organized so you can move from big-picture planning to practical action. First, you’ll see what “good” looks like in micro layouts; next, you’ll learn how materials and manufacturing choices influence comfort and longevity; then, we’ll cover installation, utilities, permissions, and money. Along the way, we’ll compare capsules to conventional builds and other small-space formats to keep expectations grounded.

Outline of the journey ahead:

– Design and Space Optimization: translating human-scale measurements into calm, compact layouts.

– Materials, Manufacturing, and Durability: the trade-offs between metal, timber, and composite shells.

– Installation, Utilities, Regulations, and Budgeting: site prep, hookups, approvals, and realistic costs.

– Decision Roadmap and Conclusion: matching use cases to configurations and making a confident go/no-go call.

Why capsules, and why now? Offsite fabrication can cut on-site labor and weather delays, which often drive budget creep. Consistent factory conditions enable tighter tolerances, improving airtightness and acoustic control. When modules are standardized, operators can scale quickly, swapping or relocating units to follow demand. For homeowners, a single unit can function as a quiet office, a guest suite, or a stepping stone for intergenerational living. For institutions, repeatable pods help align capex with phased growth. The key is informed planning—understanding how size, structure, and systems interact so your small space feels coherent rather than cramped.

Design and Space Optimization

Great micro-living doesn’t start with furniture; it starts with proportions. Begin with the human body in motion—shoulder width, reach, and turning radius—then allocate clear paths first and storage second. A sleep-first capsule might measure roughly 1.2–1.5 m in width and 2.0–2.4 m in length internally, enough for a bed, lighting, ventilation, and small shelving. A day-night studio capsule typically spans 6–15 m², with 2.2–2.4 m ceiling height to relieve visual pressure. Within that envelope, prioritize three zones: entry and stowage, work or lounge, and sleep. Wet functions (toilet, shower, mini-galley) are best consolidated along one wall to simplify services.

Layout levers that unlock space:

– Doors: sliding or pocket doors keep swing clearances from eating floor area.

– Furniture: wall-mounted desks, fold-down beds, and bench-lid storage reduce clutter without sacrificing function.

– Verticality: overhead lockers and lofted shelves free the floor for circulation.

– Light and air: a narrow window high on the wall offers privacy while borrowing sky; cross-ventilation prevents stale zones.

– Acoustics: aim for assembly sound ratings that limit voice transmission; quiet capsules feel bigger because you can unwind.

Micro-living also benefits from “modes.” Day mode opens space for work or stretching; night mode converts seamlessly to sleep. Designing for modes means integrating mechanisms that move easily and endure daily cycles. Hinges, gas struts, and slide tracks should be selected for cycle counts, not just aesthetics. Visual order matters too: unified color tones, a limited material palette, and concealed cabling calm the eye. Mirrors placed to reflect natural light can extend perceived depth without adding active floor area.

How do capsules compare to other small formats? Relative to a travel trailer or van conversion, stationary capsules gain thermal performance and acoustic separation thanks to thicker walls and continuous insulation. Compared with a studio apartment, capsules trade expansive kitchens and storage for quick delivery and lower site impact. In campus or workforce settings, grouping capsules around shared kitchens and lounges balances privacy with community infrastructure. The design goal is not to cram everything in, but to edit deliberately so every element earns its keep.

Materials, Manufacturing, and Durability

The shell is a capsule’s climate shield and structural backbone. Common options include steel-framed panels, engineered timber frames, structural insulated panels (SIPs), and molded composites. Each path shapes weight, insulation, sound behavior, and maintenance. Steel frames deliver rigidity and slim profiles; with anti-corrosion coatings and thermal breaks, they manage weather well but require careful detailing to avoid cold bridges. Timber frames offer warm interiors and easy modification, with modern adhesives and fasteners supporting durable connections. SIPs integrate structure and insulation, speeding production while creating a continuous thermal layer. Composites can resist moisture and reduce seams, though repairs may require specialized techniques.

Typical enclosure targets to consider:

– Walls: effective R-values commonly in the R-13 to R-21 range for temperate zones; higher in cold climates.

– Roofs: R-30 to R-40 where winter dominates, less where summers are mild and shading is strong.

– Glazing: double or selective coatings to control heat gain while preserving daylight.

– Air sealing: aim for tightness that supports controlled ventilation rather than uncontrolled drafts.

In the factory, repeatability is the advantage. Jigs and templates hold components square; CNC-cut panels reduce cumulative error; pre-wiring and plumbing harnesses limit on-site variability. Quality checks typically cover structural connections, leak tests for wet rooms, insulation coverage, and electrical continuity. The outcome is fewer surprises after delivery. Durability hinges on moisture management: capillary breaks at the base, ventilated cavities where cladding demands it, and flashings that drain rather than trap water. Interior finishes should tolerate frequent cleaning—laminates, coated panels, or sealed wood with rounded edges to resist chipping.

Fire and safety features deserve early attention. Noncombustible exterior cladding, fire-rated assemblies adjacent to boundaries, and interior finishes with low flame spread improve resilience. Where capsules cluster, consider compartmentation between units and continuous detection with interconnected alarms. Acoustically, wall and door assemblies that achieve speech privacy (often equivalent to 40–55 dB sound reduction in lab conditions) contribute to rest and focus. Expect a service life on the order of 15–30 years with routine upkeep, dependent on exposure, detailing, and use intensity. The governing principle is simple: select materials that match the environment, then detail joints so water, air, and sound behave predictably.

Installation, Utilities, Regulations, and Budgeting

Site work is where a well-planned capsule project feels effortless—or doesn’t. Begin with a survey to confirm setbacks, easements, and access for delivery. Choose a foundation strategy based on soil and permanence: compacted gravel pads with adjustable pedestals for reversible installations, pier footings where frost is a concern, or a shallow slab when long-term placement is expected. Provide a clear staging area and crane or forklift path, minding overhead lines and tree canopies. A single unit can often be placed in a day when the path is prepared and connections are pre-planned.

Utilities should be consolidated to a service wall. Electrical feeds typically connect via exterior junctions; plumbing may use quick-connect couplings and heat-traced lines in cold zones; ventilation requires an outdoor air path with backdraft protection. Aim for continuous mechanical ventilation sized to occupancy—roughly 15–25 cubic feet per minute per person is a common planning benchmark—supplemented by operable windows for purge air. For energy, grid connection remains straightforward; rooftop or nearby renewables can offset loads if orientation and shading cooperate. Passive measures—insulation continuity, low-leakage construction, exterior shading—reduce energy demand before you add equipment.

Permits and approvals involve two layers: land-use permissions (zoning, setbacks, parking, density) and building safety (structure, fire, accessibility, sanitation). Clarify whether a capsule is considered a temporary structure or a permanent dwelling in your jurisdiction; that single classification shapes requirements for foundations, egress, and fixtures. Where multiple capsules form a cluster, shared facilities may trigger additional rules for common areas. Plan lead time for inspections, especially for electrical and plumbing tie-ins.

Budgeting works best when you break costs into discreet buckets and add contingency:

– Factory module: roughly 8,000–25,000 for a sleep-first pod; 25,000–65,000 for a studio capsule with bath and kitchenette, depending on finishes and climate performance.

– Transport and set: 500–3,000 for shipping per unit (distance and escort needs matter), plus 800–2,500 for crane time where required.

– Site work: 1,500–10,000 for foundation, trenching, and utility extensions; more if upgrades are needed.

– Permitting and design: variable, often 3–10% of project spend.

– Contingency: 10–15% to cover unknowns.

Hidden costs to watch: winterization for exposed lines, sound treatment near busy streets, and stormwater measures if you add impervious area. On the revenue side, operators often compare capsules to dorm rooms or compact hospitality suites; payback depends on occupancy and rates, but the speed to opening day is a meaningful part of the value story. A realistic plan aligns scope with access, services, and approvals so installation day is a calm arrival, not a scramble.

Decision Roadmap and Conclusion

Capsule projects succeed when ambitions match constraints. Start by clarifying your primary use case—long-stay living, student housing, short-stay lodging, or a home studio—and rank what matters most: privacy, speed, reconfigurability, upfront cost, or low operating energy. With a ranked list, trade-offs become visible. If privacy is paramount, you’ll favor thicker walls, high acoustic doors, and fewer shared surfaces, accepting a slight hit to interior floor area. If speed rules, choose standardized modules and straightforward foundations rather than custom layouts that invite delays.

A simple decision path can keep you honest:

– Site realities: is there a clear delivery route and a feasible foundation type?

– Services: can you reach power, water, and waste lines without major upgrades?

– Rules: does the local code allow capsules as you intend to use them, and under what classification?

– Budget: do line items plus contingency align with funding, including soft costs?

– Operations: who cleans, maintains, and manages bookings or tenancy?

Compare capsules to alternatives based on whole-life value rather than sticker price alone. A conventional build may promise larger spaces but carries longer schedules and weather risk. Mobile accommodations can move easily but may trade thermal and acoustic comfort. Capsules sit in the middle: compact, quick, and adaptable, with comfort levels that reflect careful material and layout choices. For multi-unit sites, shared kitchens, laundry, and outdoor rooms can elevate livability without bloating each module, enabling a strong balance between privacy and community.

For homeowners, a capsule can unlock a quiet workspace or a dignified guest suite without a full addition. For operators and institutions, repeatable pods can scale with enrollment, seasonal demand, or staffing cycles. Whichever path you choose, treat the process like an engineering-informed design sprint: define needs crisply, test layouts against human measurements, pick materials for your climate, and sequence approvals early. That discipline turns a small footprint into a generous experience—and makes modular micro-living a practical tool rather than a trend.