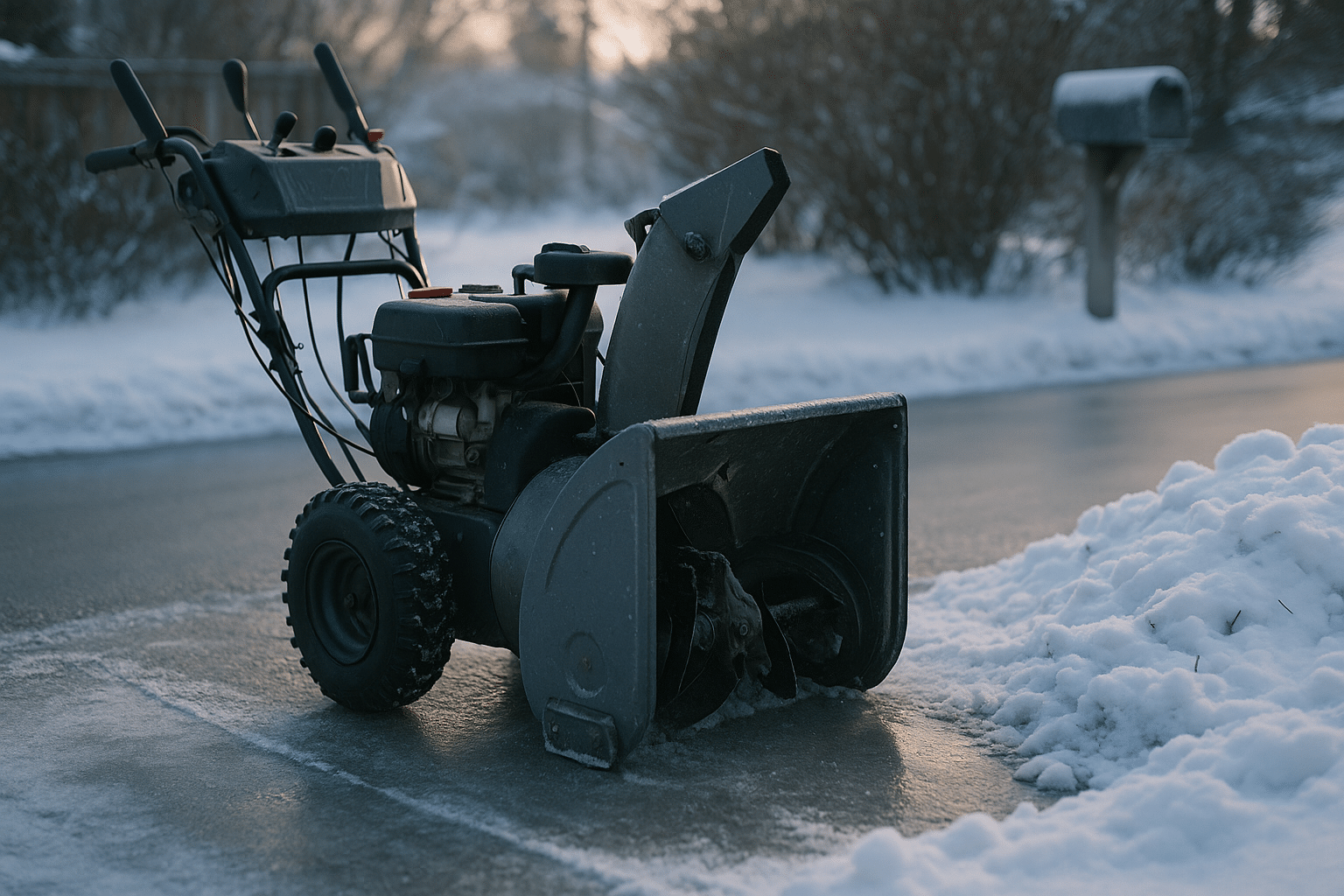

Tired of Shoveling? What to Know About Snow Blowers That Can Help You Save Time This Winter

Introduction

If your winter routine is a tug-of-war with heavy drifts, a snow blower can be the difference between a rushed morning and a calm start. The right machine matches your climate, driveway, and pace, transforming repetitive labor into a predictable task. Instead of wrestling a shovel through slush and compacted berms, you steer, adjust the chute, and let the augers do the lifting.

Choosing confidently requires more than scanning a price tag. You’ll want to think through snowfall patterns, surface type, storage space, and how much maintenance you’re comfortable managing. Power options now range from quiet electric models to muscular multi-stage designs that chew through packed ridges. With a little planning, you can trade fatigue for consistency, and long sessions for a few efficient passes after each storm.

Outline

– Types and stages: single-, two-, and three-stage designs, what each handles well

– Power sources: gas, corded electric, and battery, with runtime, noise, and maintenance considerations

– Time-saving features that matter: width, self-propel systems, chute controls, and traction

– Costs and care: purchase, upkeep, consumables, and storage

– Operation strategy: techniques and safety to clear faster with less effort

Know Your Machine: Single-, Two-, and Three-Stage Designs

Snow blowers are defined by how they move snow from ground to chute. A single-stage unit uses a rubber or composite auger to scoop and throw in one motion, contacting the surface to help pull the machine forward. A two-stage adds an impeller behind the auger to accelerate discharge, which increases throwing distance and reduces clogging in deeper accumulations. A three-stage design inserts a high-speed accelerator that breaks up heavy, compacted snow before the impeller ejects it. Each approach shines in a different winter story.

For small, paved areas with lighter, drier snow, a single-stage can be nimble and efficient. Typical clearing widths span 18 to 22 inches, with throwing distances around 15 to 30 feet. Many homeowners appreciate that a single-stage’s auger squeegees close to the pavement, leaving a clean surface on smooth concrete or asphalt. Two-stage machines step up to 24 to 30 inches wide, often clearing 1,700 to 2,200 pounds of snow per minute under ideal conditions, and can hurl snow 35 to 50 feet. They handle uneven terrain and moderate end-of-driveway berms better because the metal auger doesn’t have to touch the ground. Three-stage models target heavy, wet snow, tall plow piles, and long, wide driveways where speed and throughput pay off.

Choose based on your conditions, not just ambition:

– Single-stage: Great for sidewalks, townhome driveways, and areas with 3 to 8-inch storms; less suited to gravel.

– Two-stage: Balanced choice for mixed snow types, larger driveways, and gravel with adjustable skid shoes.

– Three-stage: Purpose-built for frequent 10-inch-plus events, dense drifts, and compacted berms.

A quick sizing example illustrates the stakes. Consider a two-car driveway about 20 by 30 feet (600 square feet). A 6-inch event creates roughly 300 cubic feet of snow. With typical densities from 10 to 20 pounds per cubic foot, that’s 3,000 to 6,000 pounds to move. A single-stage around 600 to 900 pounds per minute could clear it in 5 to 10 minutes under ideal conditions; a two-stage might do it faster, especially if the snow is heavy. Real-world variables—turns, obstructions, and wetter snow—extend those times, but the gap versus shoveling remains substantial.

Surface type matters. On gravel, set skid shoes to keep the auger housing elevated and prevent rock pickup. For pavers, ensure the scraper bar is adjusted evenly to avoid scuffs. And if your area sees frequent wind, a machine that throws farther provides more flexibility for stacking snow where it won’t blow back across the driveway.

Power Sources Compared: Gas, Corded Electric, and Battery

Power determines how your snow blower starts, runs, and sounds on a freezing morning. Gas-powered engines have long dominated mid- and large-frame machines thanks to torque and range. They typically deliver the muscle needed for high-capacity two- and three-stage frames and are paired with self-propel drivetrains. Cold starts can be reliable if maintained, but they require seasonal prep and fuel management. Noise is noticeable—often 85 to 100 dB at the operator’s ear—so hearing protection is wise.

Corded electric units trade range for simplicity. Plug in, squeeze the handle, and you’re working without fuel or oil. They’re primarily single-stage machines with clearing widths around 18 to 21 inches, and they excel on small driveways and walkways where an extension cord can safely reach. Winter-rated outdoor cords are essential, and cable management takes practice. On the plus side, noise is modest compared to gas, typically in the 70 to 80 dB range, which neighbors appreciate during early clears.

Battery-powered models have expanded rapidly, with high-capacity packs capable of powering single-stage and some two-stage designs. Runtime depends on pack size, temperature, and snowfall depth; plan for 20 to 45 minutes per charge in cold conditions, with extra packs extending sessions. Battery performance dips in sub-freezing weather, so storing packs indoors until use helps maintain output. Many users value push-button starting, low maintenance, and lower operating noise for morning or late-night clears.

Consider the trade-offs through your own lens:

– Gas: Strong performance in deep, wet snow and long driveways; requires fuel stabilizer, oil changes, and off-season storage steps.

– Corded electric: Simple and light; cord management and reach limit where you can clear.

– Battery: Quiet and low-maintenance; plan around runtime and charging, especially in prolonged storms.

Operating cost varies as well. Gas expenses include fuel, oil, spark plugs, and occasional belts or shear pins. Electricity costs per clearing session are typically low—often measured in cents rather than dollars—depending on local rates. Battery ownership shifts cost to the pack itself, with replacement cycles measured in years and charge cycles; care and storage practices affect longevity. Emissions considerations and neighborhood noise rules can also steer choices, as some locales now limit certain small-engine use. Matching power source to driveway length, snowfall intensity, and maintenance comfort ensures your purchase pays back in saved time instead of added hassle.

Features That Actually Save Time

Not every feature earns its keep when the flakes fly. Focus on elements that cut minutes and reduce frustration. Clearing width and intake height set the baseline. Wider machines move more snow per pass, but a tight walkway or a short turnaround area can favor a slightly narrower unit for easy maneuvering. Intake height matters in regions that see tall drifts; more height keeps you from bulldozing and stalling in heavy accumulations. Pair this with a metal auger and impeller combination for consistent discharge in mixed conditions.

Self-propel systems are major time-savers on two- and three-stage models. Multiple forward speeds let you match pace to snow depth, while reverse saves your back in tight spaces. Look for chute controls you can operate without stopping—joysticks, levered deflectors, or quick-turn cranks are all designed for on-the-fly adjustments. The goal is to redirect snow once and keep moving rather than reworking the same strip because it blew back at you.

Traction deserves a close look. Deep tread tires with chains or a track drive provide grip on steep or icy surfaces. Adjustable skid shoes protect gravel and uneven surfaces, while a durable scraper bar helps squeegee the last layer on smooth pavement. Anti-clog designs, larger discharge chutes, and robust impeller housings increase reliability in wetter snow. Small touches still matter on cold mornings: heated handles, a simple tool-less chute cleanout, and a headlight for predawn clearing can elevate the experience without inflating complexity.

Prioritize features that directly improve throughput:

– Self-propel with multiple speeds to maintain momentum.

– One-handed chute and deflector controls to minimize stops.

– Traction aids (chains or tracks) for hills and ice.

– Adjustable skid shoes and scraper bar alignment for surface protection.

– Folding handles or compact storage dimensions when space is tight.

Durability details pay dividends over several winters. Reinforced auger housings shrug off occasional packed ice, and easily accessible shear pins protect drivetrain components during surprise encounters with debris. If your area sees frequent slush followed by freezes, corrosion-resistant finishes and frequent rinse-downs help keep components moving freely. In short, features that reduce fiddling, rework, and slip risk are the ones that turn a chore into a straightforward routine.

What It Really Costs: Budgeting, Maintenance, and Total Ownership

Buying a snow blower is more like choosing a reliable tool than making a seasonal splurge. The sticker price is only part of the story. Single-stage corded or battery units often price in the lower to middle range, while gas two-stage machines sit higher due to larger frames and drivetrains. Three-stage designs and wide commercial-style units command a premium. Think in terms of cost per season, not just day-one numbers, and weigh how often you clear, how long each session lasts, and what your time is worth.

Ownership includes consumables and care. Gas models need oil changes, fuel stabilizer, air filters, and spark plugs at set intervals, along with fresh shear pins and occasional belts. Electric machines trade most of that for inspections of cables, batteries, and connections. Expect to sharpen or replace scraper bars and skid shoes periodically, especially if you cover large areas or encounter rough surfaces. Tires may need chains, and tracks benefit from tension checks. A simple annual tune-up before the first storm often prevents mid-season downtime.

Maintenance flow that keeps machines ready:

– Early fall: Inspect belts, cables, scraper bars, and skid shoes; run the machine briefly.

– First snow alert: Charge batteries, prep fuel with stabilizer, and stage extension cords if applicable.

– Mid-season: Re-torque hardware, clear salt buildup, and check chute rotation for binding.

– Off-season: Drain or stabilize fuel, clean thoroughly, and store in a dry, ventilated space.

Operating costs vary by power source. A typical single-stage electric session can cost well under a dollar in electricity, while gas consumption depends on engine size and workload. Batteries amortize over years; keeping packs at moderate charge and temperature extends useful life. Also consider hidden costs: space in the garage, a cover to reduce dust and moisture, and a small parts kit for pins, bolts, and shear pins so a minor break doesn’t halt a storm-day clear.

Finally, evaluate return in saved time. If a two-stage cuts a 45-minute shovel job to 12 minutes across a dozen storms, you’ve banked several hours and avoided a good deal of strain. For households balancing school drop-offs, commutes, and night shifts, predictability has real value. Choosing a machine that you will maintain—rather than one that looks impressive but sits unused—keeps the cost of ownership firmly in your favor.

Operation Strategy: Techniques and Safety for Faster Clears

Technique can make a modest machine feel mighty. Start by watching the wind; aim the chute so snow rides the breeze away from your cleared path. Work “with” the storm when possible—quick passes during a lull prevent the weight of a full-depth clearing. If your area gets frequent plow berms, address the end of the driveway early, then return for a final pass after the street is finished. Overlap each pass slightly to avoid thin ridges that require rework later.

Pattern matters. In wide driveways, clear the upwind edge first and throw snow downwind to keep the surface clean as you advance. On narrow paths, a center-out approach prevents walls that collapse back into your work area. For thick, wet snow, take half cuts to keep load on the impeller manageable and reduce clogging. If the chute begins to sputter, slow the ground speed rather than forcing more volume; consistent feed yields longer throws and fewer jams.

Prepare for efficiency and safety:

– Mark hazards with tall stakes before the ground freezes—sprinkler heads, curbs, and low planters.

– Keep a non-marring cleanout tool handy; never use hands to clear the chute or auger.

– Wear traction aids on boots and protect ears and eyes; snow and grit can rebound unexpectedly.

– Let the machine cool outdoors after use before storing to avoid fumes in enclosed spaces.

– Keep children and pets indoors while operating; discharge snow away from windows and parked vehicles.

If your driveway is gravel, raise the housing via skid shoes to avoid picking up stones. On slopes, work across the gradient rather than directly up or down when possible, and use lower speeds for control. In extreme cold, batteries should be staged indoors until the moment you head out; for gas engines, a brief warm-up stabilizes idle and reduces stalling. After the final pass, brush off salt and slush to limit corrosion, and check that chute rotation and deflector hinges remain free. Small habits—anticipating wind, setting the right speed, and staging tools—compound into shorter, cleaner clears throughout the season.

Conclusion: A Clear Path to Smarter Winter Mornings

The right snow blower turns winter from a scramble into a manageable routine. Match machine type to your snowfall and surface, choose a power source that fits your maintenance comfort, and prioritize features that keep you moving. Add a simple care plan and a smart clearing pattern, and you’ll reclaim time on every storm day. Whether you’re managing a compact walkway or a long driveway, a well-chosen, well-used machine can keep mornings predictable and evenings free of back-and-forth battles with the shovel.