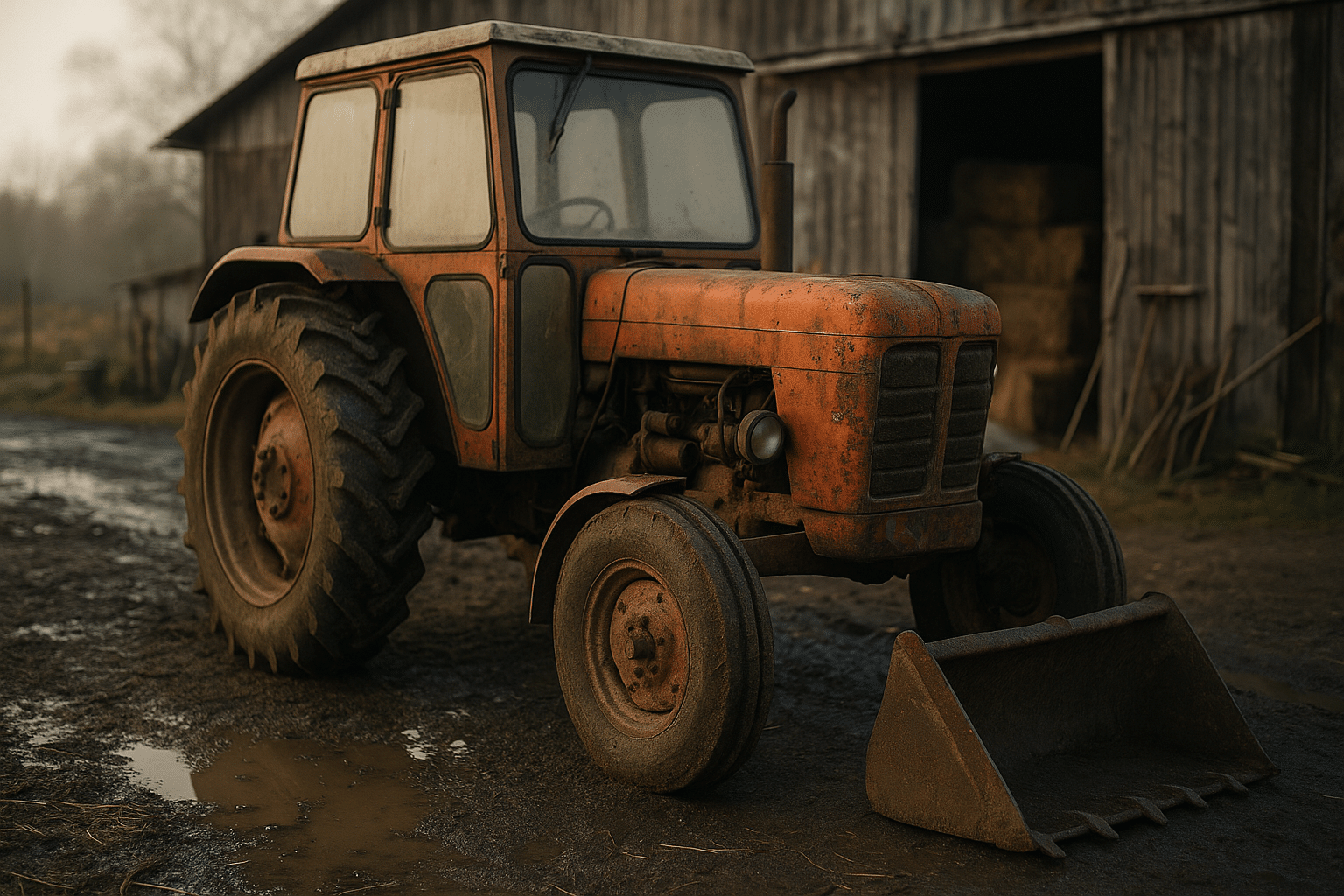

Buying a Used Tractor: Inspection Checklist, Pricing Factors, and Reliable Sources

Outline:

1) Why buying used tractors matters: value, relevance, and matching power to tasks

2) Inspection checklist: powertrain, hydraulics, PTO, electrics, structure, and tires

3) Reading wear and history: hours, usage patterns, and maintenance records

4) Pricing and total cost of ownership: market factors, negotiation, and hidden costs

5) Reliable sources and sealing the deal: where to buy and how to close confidently

Why Buying Used Tractors Matters: Value, Fit, and Long-Term Utility

For many landowners, growers, and contractors, a used tractor strikes a smart balance between capability and cost. New machines can carry steep price tags and immediate depreciation, while well‑kept used units often deliver steady performance at a fraction of the investment. The key is to align power, weight, and hydraulic capacity with the real work on your list—mowing pasture, loader work around a yard, baling hay, or pulling ground‑engaging implements. When the tool fits the task, the savings compound in practical ways: lower upfront cash outlay, less risk exposure, and room in the budget for attachments that amplify productivity.

Depreciation is one reason buyers lean used. Tractors don’t follow the same curve as consumer cars, but value commonly softens most in the early years, then levels as the machine proves durable. A unit that’s a decade old with clean maintenance and sensible hours can still offer thousands of productive hours. Usage intensity matters: a compact utility tractor used for mowing and light loader work may add 100–200 hours per year; a larger field tractor can log 500–1,000 or more. Knowing your expected annual hours helps you avoid overbuying horsepower you won’t use or underbuying capacity that strains the machine.

Fit goes beyond engine size. Consider wheelbase and weight for stability on slopes, tire type for your terrain, and hydraulic flow for attachments. A loader, rear remote valves, and a reliable three‑point hitch can be worth more than raw horsepower if your jobs involve frequent implement changes. Comfort has value, too. An operator who can see well from the seat, reach the controls easily, and stay out of the weather tends to work longer and safer. Think of it as investing in dependable labor; a tractor that suits your work style becomes a steady teammate.

Practical planning pays off. Sketch your task list across a season and rank what matters most:

– Implement compatibility and hydraulic needs

– Traction and tire type for soil, turf, or snow

– Storage space, transport width, and gate access

– Maintenance you’re comfortable doing vs. hiring out

When you clarify these realities upfront, the used market opens in a useful way, revealing machines that meet your needs without costly extras you’ll never use.

The Field-Tested Inspection Checklist: From Cold Start to Final Pass

Arrive early and ask for a cold start. A diesel that lights quickly, idles smoothly, and stabilizes without excessive smoke is a good opening note. Listen for metallic knocks, irregular idle, or hunting RPMs. Light gray smoke at start can be normal; sustained blue smoke suggests oil burning, while dense black under light load may indicate fueling or air issues. Check the exhaust visually and with a clean rag held briefly a safe distance away; oily residue can be a red flag.

Engine bay and fluids:

– Oil: look for clean level and no “milkshake” appearance that hints at coolant contamination

– Coolant: inspect color and clarity; check for crusted leaks around hoses and radiator

– Fuel system: look for damp lines, cracked hoses, or makeshift filters

– Belts and hoses: check tension, cracks, and glazing

A compression test and oil analysis add confidence if the seller permits a pre‑purchase check through a local shop.

Drivetrain and motion:

– Clutch: slip test on an incline in a safe area; engagement should be consistent

– Transmission: shift through all gears under load; hydrostatic drives should pull without whine that worsens dramatically under moderate work

– Four‑wheel drive and differential lock: engage and verify function in low‑traction conditions

Steering should feel direct. Excessive play can point to worn linkages or front axle pivots. Brakes must stop straight and confidently.

Hydraulics and PTO:

– Loader: raise to full height, hold, and watch for drift; curl and dump repeatedly to gauge speed and power

– Three‑point hitch: lift a load, hold, then shut the engine off; rapid settling signals internal leakage

– Remote valves: cycle with an attachment to verify pressure and return flow

– PTO: engage at rated speed; vibration or grinding indicates bearing or clutch issues

Chassis and structure:

– Frame rails, bell housing, and loader mount points: inspect for cracks, torch marks, and odd welds

– Front axle trunnions and kingpins: look for looseness and grease patterns that imply neglect

– Tires: check tread depth, sidewall cracks, and fluid ballast leaks; uneven wear may suggest alignment or bearing issues

Electrics and cab: verify lights, gauges, hour meter function, glow plugs, and charging voltage; inspect wiring for neat, fused add‑ons rather than twisted splices. A careful hour‑by‑hour test drive—idle, mid‑range, and working RPM—provides the telling final pass your eyes can’t.

Reading Wear, Hours, and Service History Like a Pro

Hours matter, but they’re only one chapter in a longer story. Machines with modest hours but poor upkeep can be more troublesome than higher‑hour units with disciplined service. Start with patterns: pedal surfaces polished to a mirror, a steering wheel worn smooth, and sloppy linkage suggest heavy use. Fresh paint that doesn’t match fasteners or overspray on hoses may be a cosmetic patch, not a mechanical fix. Conversely, plain‑spoken wear—sun‑faded paint, tidy grease around zerks, and scuffed but intact controls—often reflects honest work.

Service records are worth their weight. Look for dated entries covering engine oil and filters at reasonable intervals, fuel filter changes, air filter inspections, coolant maintenance, and documented hydraulic and transmission services. On many tractors, engine oil is changed every 100–250 hours depending on duty cycle and environment, with hydraulic and transmission fluids on longer intervals. Consistency beats perfection: even if a previous owner stretched one interval, a pattern of timely care is reassuring.

Usage type shapes wear. Loader‑intensive work stresses front axles, steering components, and loader pins; row‑crop or hay work leans on PTO clutches, gearboxes, and hydraulics; constant mowing means lots of mid‑RPM hours and debris exposure. Match observed wear to likely tasks. If loader bushings are egg‑shaped but the machine claims “light use,” ask questions. If PTO engagement is crisp and quiet on a unit that ran mowers and balers, that aligns with the story.

Hour meters can be replaced or fail. Cross‑check with:

– Seat foam collapse, pedal pad wear, and floor scuffs

– Play in the three‑point hitch ends and loader pins

– Condition of the drawbar, top link threads, and hydraulic couplers

– Age‑consistent fasteners and hoses vs. a few brand‑new parts in isolation

As for engine longevity, well‑maintained diesels commonly deliver several thousand hours before major internal work, but environment and operator habits make large differences. Cold starts without warm‑up, dusty intake leaks, and skipped filters shorten the arc; clean fuel, correct oils, and gentle ramp‑ups lengthen it.

When the paper trail is thin, create your own. Request a pre‑purchase inspection by a trusted mechanic, run an oil analysis, and budget for a baseline service the day you bring the machine home. That first round—fluids, filters, belts, and a complete grease job—establishes a firm starting point and can uncover minor concerns before they become expensive.

Pricing, Depreciation, and Total Cost of Ownership (TCO)

Price is a blend of capability, condition, and context. Horsepower class, drive type, loader presence, and age set the initial lane. Clean documentation and careful upkeep nudge values higher, while neglected maintenance and mismatched wear pull prices down. Region matters: dry‑climate machines often show less rust, while strong local demand can raise prices during planting or hay seasons. Compare multiple recent sales of similar horsepower, drive, and features to anchor a fair range—then adjust up or down for condition and included implements.

Attachments can swing value significantly:

– Front loader with quick‑attach bucket: often adds 10–25% depending on size and condition

– Rear remotes, third‑function hydraulics, and power‑beyond: appreciated by implement users

– Mowers, blades, post‑hole diggers, and snow implements: convenient but assess each piece on condition, not bundle hype

Tires deserve special attention. A pair of new rear ag tires can run into the low thousands depending on size; turf and industrial tires vary similarly. Heavily cracked sidewalls or mismatched pairs justify negotiation because they affect traction, safety, and soil impact.

TCO reaches beyond the bill of sale. Factor in:

– Immediate catch‑up maintenance (fluids, filters, belts, battery)

– Wear items (pins, bushings, hoses, seat, lights)

– Insurance, storage, and transport

– Fuel consumption for your duty cycle

An initial baseline service can range from a few hundred dollars upward depending on fluid capacity and filter count. Major repairs vary widely: a hydraulic pump or clutch job may be a mid‑four‑figure expense on larger machines; engine overhauls scale with displacement and parts availability. These are not scare tactics—they are planning tools that prod you to leave cushion in the budget.

Negotiation works best when grounded in facts. Bring printouts or notes on comparable sales, tire quotes, and the cost of missing features you’ll need (for example, adding a third‑function valve). Offer a fair figure that reflects condition and your immediate service costs, and be prepared to walk politely. Sellers recognize informed buyers. Aim for a price that lets you care for the machine properly after purchase rather than spending every dollar at the handshake.

Reliable Sources, Buying Paths, and a Practical Closing Checklist

Where you shop shapes what you get. Each channel has its personality, and understanding the trade‑offs saves time and reduces risk.

Local equipment dealers: Typically provide some level of inspection, clear paperwork, and a place to return with questions. Prices may sit higher, but so does convenience. Ask about recent service, trade‑in evaluations, and any return window for latent defects discovered immediately after delivery. Community reputation matters; long‑standing operators value repeat customers and are more likely to disclose small quirks.

Private sellers: Often priced attractively, with rich backstories about the machine’s work. Verify ownership, request maintenance notes, and insist on a thorough test. Meet at the property where the tractor lived—seeing the terrain and implements adds context. If the unit is still in seasonal work, that’s a good sign; a machine parked for years needs extra scrutiny of seals, hoses, and electrics.

Consignment lots and auctions: Wide selection, quick decisions, and “as‑is” conditions. Preview days are your friend—conduct the full inspection then. Set a ceiling number before bidding, including your transport and immediate service costs. If you lack experience, bring a knowledgeable friend or hire a mechanic for an hour; the fee can save a misstep.

Institutional and fleet retirements: Municipal or corporate fleets often keep meticulous service logs and follow scheduled maintenance. Hours can be higher, but consistent care is a plus. Check for idle time and short‑cycle use—machines that ran plows or loaders in tight quarters may show front‑end wear despite clean records.

Protect the transaction with a simple closing routine:

– Confirm serial number and compare to paperwork; check for liens where applicable

– Document condition with photos and a written bill of sale listing included implements

– Ask for operator’s manuals and torque specs if available

– Arrange safe transport and secure tie‑down points before moving

– Perform a complete baseline service on arrival and record it for your own future resale

Conclusion: The used tractor market rewards patience, curiosity, and a willingness to test. Start with a clear task list, lean on a disciplined inspection, and price with total ownership in mind. Reliable sources exist in every region; they stand out when the story, the wear, and the records point in the same direction. Approach the search like a season’s work—steady passes, tidy edges, and no rush—and you’ll bring home a dependable machine that earns its keep without drama.