Used Trailer Guide: Prices, Key Features, Benefits, and Buying Tips

Outline and Why Used Trailers Matter Right Now

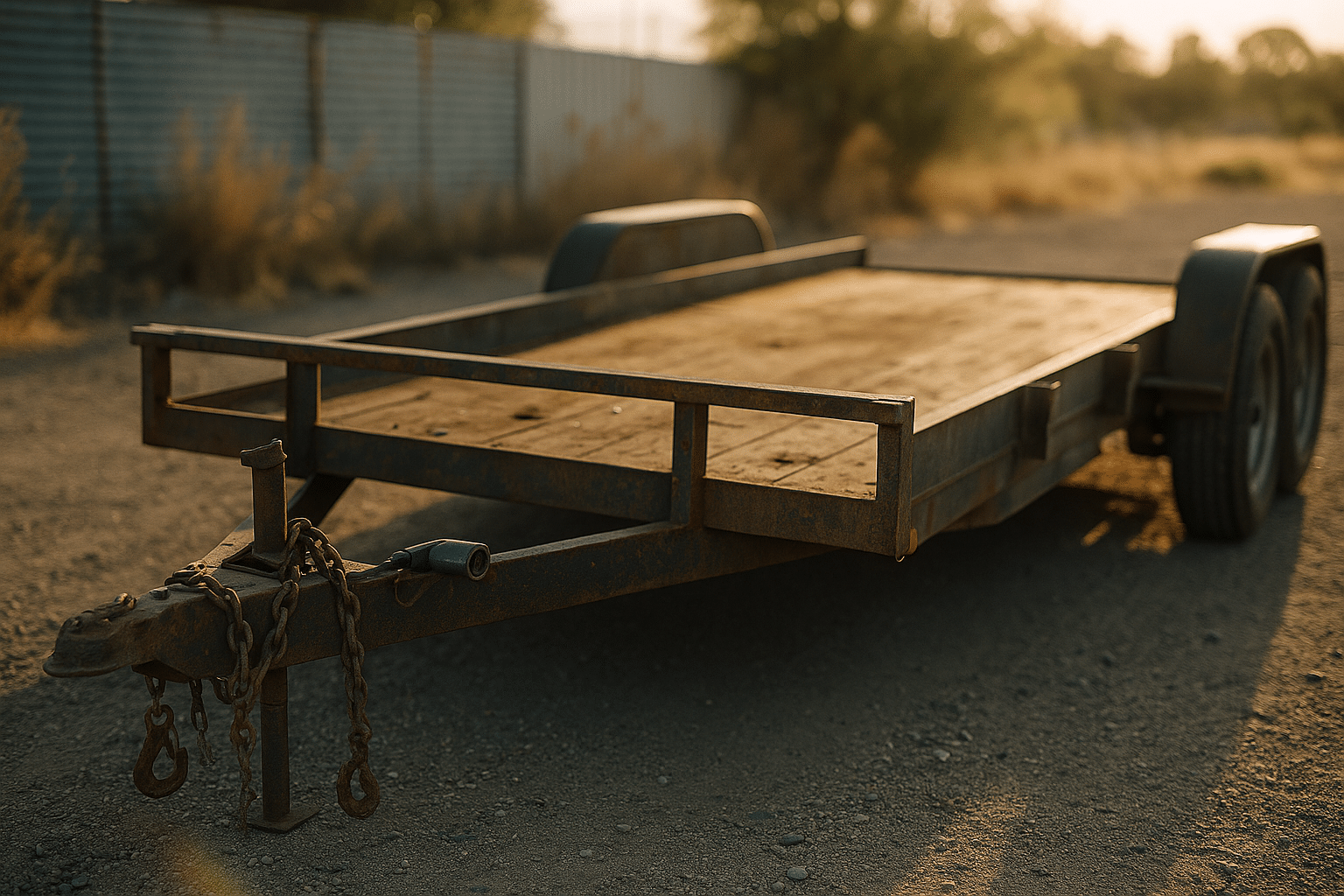

Before diving into grease fittings and price tags, it helps to have a map. The used trailer market is wide, practical, and surprisingly nuanced: small utility trailers handle yard work and DIY jobs, enclosed cargo units shield tools and inventory from weather, car haulers move prized rides, equipment and dump models shoulder heavy-duty tasks, and goosenecks offer stability for long hauls. Buying used can save significant money, reduce depreciation, and put you on the road sooner, but it also requires a careful eye and a plan. Think of this guide as a flashlight in the yard at dusk—illuminating the corners where value hides and problems tend to lurk.

This article unfolds in five parts so you can skim or study as needed:

– Prices and cost factors: typical ranges by trailer type, age, materials, and condition, plus total ownership costs.

– Features and inspection: frames, axles, brakes, lighting, decking, and hitches—what to check and why it matters.

– Benefits of buying used: savings, availability, accessories, and environmental upsides—alongside the trade-offs.

– Buying process and negotiation: step-by-step checklists, test-tow tactics, paperwork, and safe closeout.

– A concluding roadmap: how to match a trailer to your needs and avoid common pitfalls.

Why used trailers are compelling: depreciation on new units can bite early, while used pricing tends to stabilize. Accessories like tie-down points, toolboxes, ramps, or winches are often already installed, adding real value. In many regions, trailers also carry lighter registration fees and modest insurance costs compared to powered vehicles. On the flip side, rust, worn tires, tired brakes, or questionable wiring can turn a bargain into a fixer-upper. The key is to normalize what you see: some surface oxidation is ordinary for steel frames, and wood decks darken with age, but cracked spring hangers or soft flooring are warning signs. With a structured approach, you’ll separate cosmetic blemishes from structural concerns and pay for the former, not the latter.

Prices, Cost Drivers, and Total Cost of Ownership

Used trailer prices vary by type, size, region, and season, but certain patterns hold steady. Small open utility trailers commonly range from roughly $600 to $2,500 depending on deck size, gate condition, and tire/brake state (many are single-axle and may not have brakes). Enclosed cargo trailers, valued for security and weather protection, commonly list from about $2,000 to $8,000, with height, length, and door configurations driving price. Car haulers often land around $3,000 to $9,000; aluminum frames typically command premiums for corrosion resistance and lighter weight. Heavy equipment or deckover models can reach $5,000 to $18,000 used, as higher GVWR, dual axles, and robust frames add cost. Dump trailers, prized for hydraulics and reinforced beds, frequently range $6,000 to $15,000 used, conditioned by cylinder health and battery age.

What sets price apart is not just size but condition and spec. Key cost drivers include:

– Frame and material: steel is common and strong; aluminum trades higher upfront cost for corrosion resistance and lower weight.

– Axles and brakes: dual- or tri-axle configurations spread load but add maintenance; electric brakes are typical, surge brakes appear on some older units.

– Age, usage, and service history: trailers stored outdoors show weathering; receipts for tires, bearings, and brake parts help justify asking price.

– Regional demand and seasonality: spring and early summer listings move quickly; late fall can yield opportunities as sellers reduce inventory.

Total cost of ownership matters as much as purchase price. Budget for the following in your first year:

– Tires: $80–$200 each depending on size and load rating; consider all five if there’s a spare.

– Bearings and seals: $100–$250 per axle for inspection, repack, and parts.

– Brakes: $150–$400 per axle for shoes/pads, drums/rotors resurfacing or replacement, and magnet/hardware as needed.

– Lighting and wiring: $30–$200 for connectors, bulbs or LEDs, and repairs to grounds or corroded splices.

– Hitching gear: appropriate ball mount, coupler lock, tie-down straps, or weight distribution components if required.

– Registration/taxes: varies widely by jurisdiction; plan a buffer to avoid surprises.

Finally, weigh fuel economy and payload. Aluminum frames and proper tire inflation reduce rolling resistance; matching the trailer’s GVWR to your actual needs helps you avoid overpaying for capacity you will not use. A clear, itemized budget up front makes negotiating easier and prevents a “cheap” trailer from becoming expensive after the handshake.

Key Features and Inspection Checklist: How to Spot Real Value

Evaluating a used trailer is a hands-on exercise. Start with the frame: sight down the rails for straightness; look for bends near the tongue and at the spring hangers; tap suspicious areas for thin metal. Surface rust on steel is common, but scale flaking, perforations, or weld cracks are red flags. On aluminum frames, check for galvanic corrosion around dissimilar metal fasteners and at crossmembers; white, powdery oxidation near hardware deserves scrutiny. Examine all welds for uniformity and signs of repairs; neatly ground welds with consistent bead patterns often indicate careful workmanship.

Axles and suspension take a beating and repay careful inspection. For leaf springs, look for cracked leaves, sagging packs, and worn bushings; check equalizers on tandem setups for slop. Torsion axles should sit at an expected ride height; a “squatting” corner can hint at a tired rubber core. Tires tell stories: uneven wear suggests alignment, bent axles, or overloaded use. Verify load rating and speed rating match the trailer’s GVWR and intended use. Spin wheels and listen for rough bearings; feel for play by shaking at 12 and 6 o’clock.

Brakes and safety systems separate a safe deal from a risky one. Electric drum brakes should engage smoothly in a parking-lot test; inspect magnets and wiring near backing plates for chafe. Surge systems should not leak and must compress/release smoothly; a spongy actuator needs attention. Confirm the breakaway kit is present, wired to a dedicated battery, and actually locks wheels when pulled. Safety chains must be undamaged and correctly sized; inspect coupler latch for positive engagement on the correct ball size.

Decking and enclosures deserve time. For wood decks, probe for soft spots at the ends and around fasteners; cupping and checking are normal but rot is not. On enclosed units, check for roof leaks at seams and vents; water stains inside can betray old issues. Doors should close squarely with weather seals intact; rollers and hinges need free movement. Lighting should be bright and consistent; corrosion often hides under ground points and inside junction boxes. A 4-pin harness covers basic lighting; a 7-pin adds brakes and auxiliary power—match this to your tow vehicle.

Paperwork confirms what your eyes see. Verify VIN legibility, weight ratings (GVWR/GAWR), and matching numbers on frame and title. Look for a data plate with tire pressure recommendations. If you can, weigh the trailer empty to validate capacity claims. A calm, methodical inspection yields leverage and protects your budget.

Benefits of Buying Used—and the Trade-offs to Consider

The headline advantage of used trailers is value. You’re skipping the steepest stretch of depreciation and often gaining bolt-on upgrades at no extra cost. Toolboxes, e-track or D-rings, spare mounts, ramps, ladder racks, winches, and stabilizer jacks frequently come included. That can save several hundred dollars in accessories alone and hours of installation time. Availability is another perk: the used market can deliver the exact size or configuration you need faster than waiting for a special order, especially during busy seasons when new inventory is tight.

Financially, used ownership can be gentler on cash flow. Insurance is typically modest, registration fees are predictable, and maintenance is straightforward if you start with a solid baseline service. For many buyers—landscapers, contractors, hobby racers, ranchers, and DIY renovators—the right trailer pays back through time saved and jobs completed. There’s also an environmental angle: extending the life of an existing trailer reduces the demand for new materials and energy-intensive manufacturing, a practical nod to sustainability without compromise on capability.

That said, trade-offs are real. Unknown service history means you may inherit deferred maintenance—bearings overdue for grease, tired tires, faded wiring, or brake shoes near their wear limit. Cosmetic wear is expected, but structural issues are costly, so inspection discipline matters. Financing can be more limited for private-party used units, and warranties are rare outside of certain dealer programs. You’ll also need to confirm compatibility with your tow vehicle: tongue weight, total weight, and brake controller requirements must align with manufacturer ratings. Lastly, resale varies by region and season; an enclosed cargo trailer may move quickly in urban areas, while a heavy deckover might attract buyers in agricultural regions.

To balance the equation, budget for an initial refresh—tires if aged out, a full bearing service, brake check, and lighting cleanup—and factor that into your offer. Approach a used trailer as you would a tool: the right one becomes an extension of your work and weekends, quietly doing its job mile after mile. With realistic expectations and a plan, the benefits often outweigh the compromises.

Smart Buying Process, Negotiation, Paperwork, and a Practical Conclusion

A step-by-step approach keeps emotions in check and protects your wallet. Start with a needs assessment: cargo size and weight, loading style (ramps, dovetail, side gates), storage footprint, tow vehicle ratings, and expected mileage per year. Shortlist two or three trailer types that fit the mission, then scan listings for consistent signals: clear photos of the frame and suspension, honest descriptions of flaws, and mention of recent maintenance. Call sellers with targeted questions and ask for cold-start videos of brake actuation or detailed shots of critical welds if you cannot visit immediately.

At inspection, treat it like a mini pre-purchase exam:

– Bring a flashlight, tape measure, tire gauge, gloves, and a multimeter or test light.

– Check VIN, plates, and title against the frame stamp; verify there are no liens if your jurisdiction tracks them.

– Conduct a coupler fit test, confirm safety chain length/capacity, and operate the jack under load.

– Test lighting circuits at the 4- or 7-pin; look for voltage drop or intermittent grounds.

– Perform a short test tow if allowed, listening for bearing howl and brake chatter; practice a few low-speed stops to gauge braking balance.

Negotiation works best when tied to facts. Build a punch list with estimated costs and present it respectfully: “Two tires are 6 years old, bearings need service, and the breakaway battery is dead—this totals about $450; I’m comfortable at $X.” Have a firm walk-away number and stick to it. If multiple similar units are available, note comparable listings to support your offer. Be ready to move quickly when the trailer matches your criteria—good used inventory turns fast, particularly in spring.

Paperwork seals the deal. Ensure the bill of sale includes VIN, date, price, names/addresses, and “as-is” language if that’s the agreement. Take clear photos of the serial plate and any included accessories. After purchase, schedule a day-one service: bearings/seals, brake adjustment, torque lug nuts and u-bolts, clean and re-terminate grounds, and replace aged tires based on DOT date codes. Add reflective tape where appropriate, label payload limits inside the trailer or on the toolbox, and set reminders for annual inspections.

Conclusion: A used trailer is the quiet partner that turns plans into finished work—hauling lumber for a renovation, moving equipment to a jobsite, or ferrying a project car to the track. If you define needs first, price total ownership rather than just the sticker, and inspect with a checklist, you’ll convert uncertainty into confidence. Make your offer with clear math, handle paperwork carefully, and give the trailer an initial refresh. Do that, and you’ll be set up for safe, reliable towing and a purchase you’ll feel good about for years.