Wall Restoration: Techniques, Materials, and Maintenance Tips

Outline and Why Wall Restoration Matters

Before diving into tools and techniques, it helps to see the overall map. Here’s how this article unfolds—so you can jump to what you need or read end to end for a complete plan:

– Diagnosing the problem: reading cracks, stains, bulges, and moisture

– Matching techniques to wall type: masonry, plaster, drywall, stucco, and concrete

– Materials, tools, costs, and safety: what to buy, how to budget, how to protect yourself

– Maintenance planning and final takeaways: keep walls sound and attractive over time

Wall restoration is more than a cosmetic refresh. When a wall fails, it rarely announces itself loudly; instead, minor hairline cracks admit water, salts migrate to the surface, and freeze–thaw cycles widen gaps season by season. Inside, bowed plaster can signal hidden moisture or delamination. On exterior walls, crumbling mortar and hollow-sounding stucco invite wind-driven rain deeper into the assembly. Addressing problems early protects structural integrity, reduces ongoing maintenance, and can improve comfort by limiting drafts and dampness. In energy audits, uncontrolled air leakage through gaps and cracks is frequently flagged as a major source of wasted heating and cooling—another reason small fixes matter.

There is also a materials compatibility story that many owners overlook. Historic brick and stone assemblies were built to “breathe,” allowing vapor to pass through. Replacing soft, vapor-permeable lime mortar with a rigid, low-permeability mix can trap moisture, pushing damage into bricks or blocks rather than sacrificial joints. Similarly, plaster relies on a system of base and finish coats that behave differently from drywall taping compounds. Matching the repair to the wall’s original logic preserves performance and extends service life.

Lastly, restoration is a practical investment. Proactive repointing, patching, and sealing are typically far less costly than rebuilding a failed section after years of neglect. Thoughtful sequencing—diagnose, stabilize, repair, and maintain—keeps projects on track. The sections ahead translate that sequence into clear steps, real-world examples, and comparative notes so you can choose techniques that align with your wall type, budget, and timeline.

Diagnosing Wall Damage: From Hairline Cracks to Hidden Moisture

Accurate diagnosis is the cornerstone of a durable repair. Start by mapping defects systematically. Use painter’s tape to mark each issue and a fine marker to record dimensions and dates; then check again in a few weeks to see if cracks are static or growing. Hairline cracks (roughly 1/64–1/16 inch) often result from surface shrinkage or minor thermal movement. Wider vertical or diagonal cracks, step-cracks in brick joints, or horizontal cracks in foundation walls can indicate movement that warrants a structural assessment. Bulges, out-of-plane surfaces, or rapidly widening fissures are red flags for professional evaluation.

Moisture leaves clues: dark blotches that persist after dry weather, peeling paint revealing chalky white powder (efflorescence), and salt crusts along mortar joints. Efflorescence itself is not structural damage, but it signals water migration through the wall that can carry soluble salts to the surface. Persistent damp patches above grade may point to failed flashing, cracked sealant at penetrations, or compromised stucco or mortar. At interior plaster, a hollow sound when tapped lightly with a wooden dowel can indicate delamination from the lath. In basements, a musty smell, spalling concrete, or flaking coatings often traces back to poor drainage or vapor drive through cool masonry.

Simple tools improve accuracy. A moisture meter helps determine whether a stain is an active leak or a past event. A straightedge or laser reveals bulges you might miss by eye. A magnifying glass can help distinguish between a crack through the unit (brick or block) and a crack along mortar joints, which suggests a different stress path. Keep notes on orientation (vertical, horizontal, diagonal), location (corners, openings, mid-wall), and context (recent storms, new landscaping, changes in HVAC). Patterns matter as much as individual defects.

Consider the environment: exterior walls face wind-driven rain, freeze–thaw, and UV degradation; interior walls experience humidity swings from cooking and bathing. Seasonal cycles can open and close small gaps. If you see staining beneath window sills, suspect flashing or sealant. If step-cracks start at a corner of a window or door, thermal movement or settling around that opening may be at play. Remember:

– Cosmetic issues: small, stable hairline cracks; paint crazing; minor nail pops

– Serviceability issues: recurring stains; efflorescence; localized spalling; hollow-sounding plaster

– Potential structural issues: horizontal foundation cracks; progressive bulging; step-cracks spreading rapidly

When in doubt—especially with horizontal cracks in load-bearing areas, significant out-of-plane movement, or sudden changes—pause and consult a qualified professional. Accurate diagnosis ensures your chosen repair method addresses the cause, not just the symptom.

Techniques Matched to Wall Type: Masonry, Plaster, Drywall, Stucco, and Concrete

Masonry (brick or stone) repairs commonly involve repointing: removing deteriorated mortar to an adequate depth—often 2–2.5 times the joint width—and packing new mortar that matches color, joint profile, and hardness. For older masonry, lime-rich mortars (Type O or N in many classifications) provide flexibility and vapor permeability, allowing joints to act as sacrificial elements. Dense, high-strength mixes may appear tougher but can force stress into bricks, encouraging spalling. After raking out joints with hand tools to minimize vibration, lightly mist the substrate, then place mortar in lifts, compacting firmly and finishing to match the original profile. Protect fresh joints from rapid drying and rain while they cure.

Traditional plaster follows a layered system: a scratch (base) coat, a brown (leveling) coat, and a finish coat. Small cracks can be bridged with a plaster-compatible filler after widening into a shallow “V” to accept material. For delaminated areas, cut back to solid plaster, stabilize with mechanical fixings or adhesive designed for reattachment, then rebuild coats to plane. Maintain breathability—avoid sealing render or plaster with non-permeable finishes that can trap moisture in historic walls. Allow each coat to firm up appropriately before applying the next; the finish coat is usually troweled to the sheen and texture of the surrounding field.

Drywall repairs emphasize clean joints and smooth feathering. For hairline cracks, cut a shallow channel, embed paper tape with setting-type compound, and feather at least 8–12 inches beyond the joint for a seamless blend. Larger holes benefit from a backer (like a scrap board screwed behind the opening), then patched with a cut-to-fit piece. Use setting-type compound for the first coat to limit shrinkage and drying time, then top with a lightweight finishing compound. Sand lightly between coats, and prime to reveal any remaining imperfections before the final paint film.

Stucco patches succeed when you replicate the original three-coat process on lath or apply a compatible two-coat over solid masonry. Scarify the scratch coat, level with a brown coat, and finish with the correct texture—dash, sand-finish, or troweled. Mist between coats and during cure to prevent rapid drying and microcracking. Color matching often requires sample panels and patience; older stucco changes shade with age and exposure.

Concrete wall cracks divide broadly into structural and non-structural. Dry, hairline shrinkage cracks are often sealed on the surface with an elastomeric or cementitious filler to block moisture. Active, leaking cracks may be pressure-injected with polyurethane to stop water; structural cracks sometimes call for epoxy injection to glue the plane, often combined with reinforcement. If there is evidence of settlement, bowing, or rebar corrosion, defer to a qualified engineer before proceeding. Across all materials, surface preparation—cleaning dust, removing loose material, and creating a sound, textured substrate—is the quiet hero of a lasting restoration.

Materials, Tools, Costs, and Safety: Choosing Wisely and Working Clean

Materials should be selected for compatibility and performance, not just convenience. For masonry, mortar choice is pivotal. Lime-rich mixes are valued for flexibility and vapor permeability, with compressive strengths that are intentionally lower than dense cement mortars. This lets joints accommodate movement and sacrificial weathering. In many classifications, Type O and Type N mortars suit many above-grade repointing tasks on older units; Type S is stronger and is typically reserved for higher-load or more exposed conditions. For plaster, use formulations intended for base and finish coats, which set and shrink differently from drywall compounds. For drywall, setting-type compounds (often labeled by minutes to set) help with first fills; lightweight pre-mixed compounds excel at final smoothing.

Primer choice affects outcomes. Stain-blocking primers help lock in tannins and watermarks after repairs, while breathable mineral or acrylic primers support vapor diffusion on masonry and plaster. Sealants have roles at joints and penetrations, but be cautious: overly tight membranes on traditionally “breathing” walls can divert moisture into unintended paths.

Toolkits can be simple yet effective:

– For masonry: joint raker, pointing trowel, margin trowel, stiff brush, grout bag for tight joints

– For plaster: hawk, trowel, darby, corner tools, spray bottle for controlled misting

– For drywall: utility knife, taping knives (6, 10, 12 inch), sanding block, dust extraction or vacuum attachment

– For stucco: scarifier, float, finishing trowels matched to the texture

Budgeting helps you set realistic expectations. DIY material costs vary regionally, but a rough sense is useful:

– Repointing materials: roughly low single digits per square foot; labor is the bigger component

– Small plaster patches: materials often in the low single digits per square foot; texture and finish matching add time

– Drywall patch and finish: materials typically in the low single digits per square foot for compound, tape, and sandpaper

– Professional repointing or stucco remediation: commonly priced by square foot with wide ranges depending on access, height, and detailing

Time is a cost too. Lime mortars can take weeks to carbonate fully; protect them from frost and hot sun during this period. Setting-type drywall compounds may be ready for second coats in 20–90 minutes, but allow for sanding and priming cycles. Plaster coats need controlled moisture to cure without cracking; plan your schedule around cure times rather than the other way around.

Safety is non-negotiable. Dust from cutting, sanding, or raking joints can contain silica—use a respirator rated for fine particulates, employ wet methods where practical, and capture dust at the source. If your home predates 1978, test for lead before disturbing painted surfaces and follow local regulations for containment and cleanup. Wear eye protection and gloves, and secure ladders on stable ground. Keep the work zone tidy to prevent trips and tool mishaps. A clean, well-ventilated site improves results and makes every stage—from mixing to finishing—more predictable.

Maintenance Planning and Final Takeaways

Restoration should end with a maintenance plan, not just a final coat. Create a wall log: record dates, materials, batch notes, and weather conditions during application. Add photos of repaired areas so you can compare in future seasons. Schedule quick seasonal checkups to intercept small issues before they become major repairs. A few minutes spent inspecting pays back as extended service life and fewer surprises.

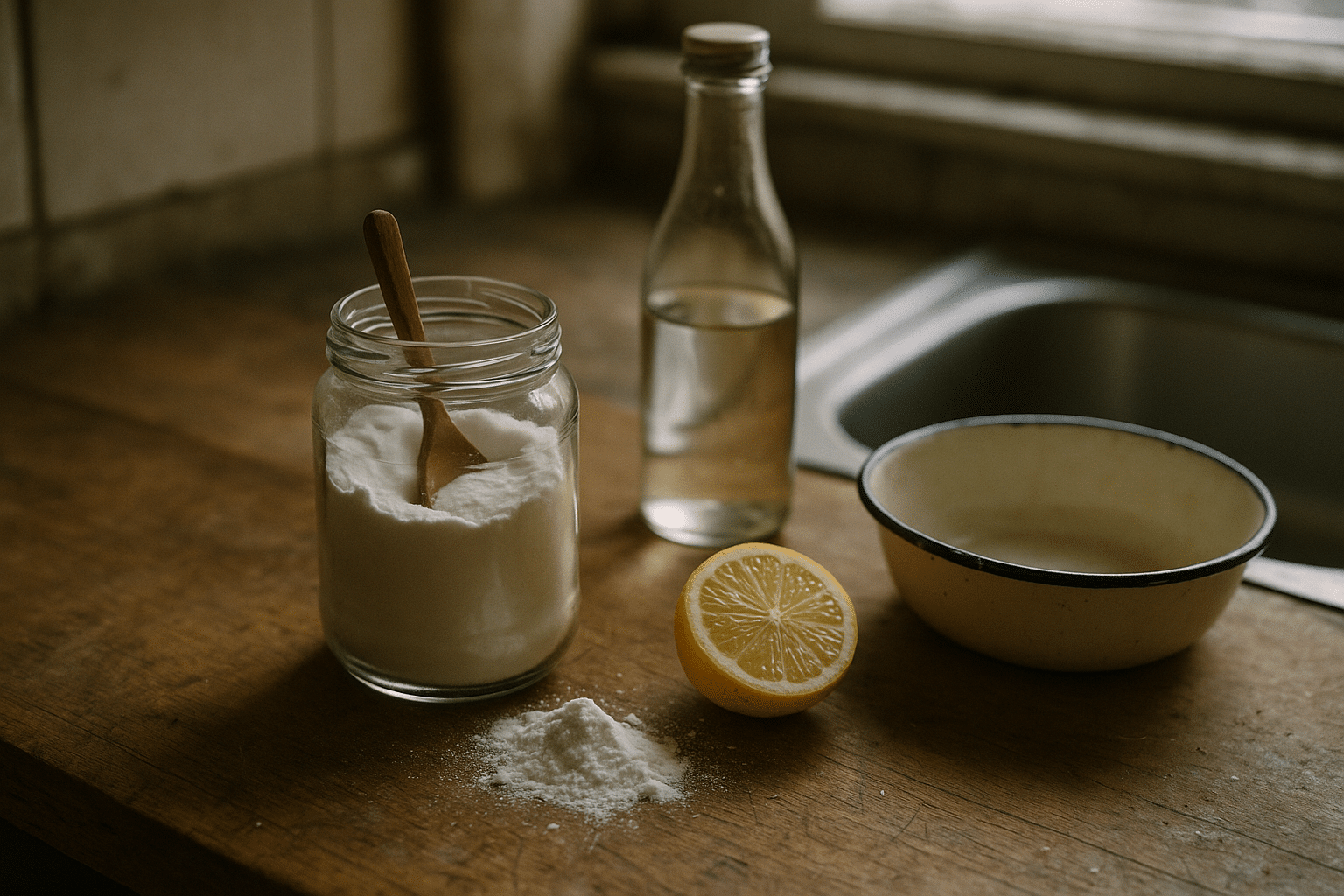

Exterior care begins with water management. Keep gutters clean, downspouts extended, and grade sloped away from foundations. Inspect sealant at penetrations and flashing at openings; replace aging beads and failed tapes. Remove vines from masonry and stucco—roots can pry into joints and hold moisture against the surface. Clean gently: soft washing or low-pressure rinsing with neutral cleaners preserves texture and avoids driving water into pores. High-pressure washing erodes mortar, etches soft brick, and can force moisture deep into assemblies.

Interior walls benefit from predictable humidity. Use exhaust fans when cooking and bathing, and if a space tends to run damp, consider a dehumidification strategy during peak seasons. Evaluate furniture placement to ensure air can move along outside walls, reducing cold spots that collect condensation. Where managing vapor is critical—basements and below-grade spaces—acknowledge that coatings are not a substitute for drainage corrections outside.

To stay ahead, keep a concise checklist:

– Spring: inspect for winter spalling, hairline changes, and efflorescence; touch up mortar and seal exterior penetrations

– Summer: manage vegetation, check stucco for hairline crazing, and mist-cure new mortar or stucco during heat waves

– Fall: verify gutters and downspouts, seal minor gaps before freeze–thaw, and review interior humidity targets

– Winter: monitor for condensation and ice buildup, note changes for spring follow-up

Final takeaways for homeowners, property managers, and hands-on renovators: diagnose patiently, respect the original material logic, and choose repairs that are compatible rather than merely strong. Small, well-timed interventions—repointing a few joints, stitching a crack, reattaching a plaster section—often prevent large, expensive failures. Budget for the invisible work of preparation and curing, because it’s where durability is won. With a sensible plan and mindful maintenance, restored walls don’t just look renewed—they perform reliably and age with character.