What is a Hydraulic Platform Lift?

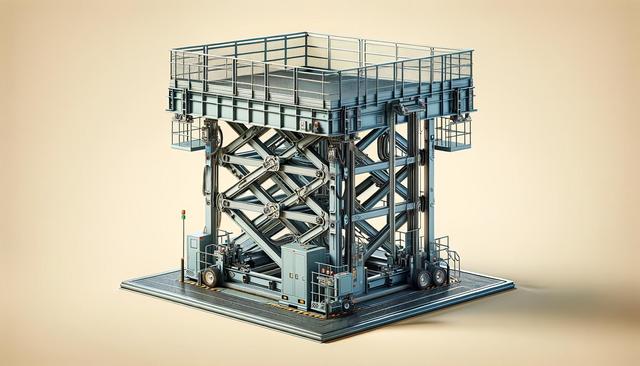

A hydraulic platform lift is a mechanical device designed to raise or lower goods or people using hydraulic power. These systems rely on fluid pressure to generate movement, making them highly effective for lifting heavy loads with minimal effort. Commonly used in warehouses, industrial facilities, residential buildings, and public access areas, hydraulic platform lifts come in various designs, including scissor lifts, vertical platform lifts, and dock lifts. They are widely appreciated for their reliability and smooth operation, especially in situations where space or structural limitations prevent the installation of other types of lifts.

Hydraulic platform lifts typically consist of a platform, hydraulic cylinders, a motor or pump, and a controller. The hydraulic fluid is pumped into the cylinders, causing the platform to rise. Releasing the fluid allows the platform to descend. The strength and flexibility of hydraulic technology give these lifts an edge in environments that require consistent performance and high load capacity.

Key Advantages of Hydraulic Platform Lifts

The popularity of hydraulic platform lifts stems from several notable advantages that make them suitable for many applications. These benefits include:

- Load Capacity: Hydraulic lifts can support substantial weights, making them ideal for industrial and commercial use.

- Compact Design: Many models require less space for installation compared to other lift systems.

- Quiet Operation: The fluid-based system ensures a smoother and quieter lifting motion.

- Safety Features: Equipped with emergency lowering functions, non-slip platforms, and safety rails.

- Maintenance: Hydraulic systems are relatively simple to maintain, with fewer moving parts than mechanical alternatives.

In addition to these advantages, hydraulic lifts can be cost-effective over the long term, especially when used in settings where frequent lifting is required. Their durability and ease of use contribute to lower downtime and improved operational efficiency.

Common Applications in Different Environments

Hydraulic platform lifts are not limited to a single industry or application. Their versatility allows them to be used in a wide range of environments, such as:

- Industrial Facilities: For moving heavy equipment and materials between floors or different workstations.

- Commercial Buildings: To provide accessibility for individuals with limited mobility.

- Residential Use: Installed in homes to assist elderly or disabled residents with vertical movement.

- Retail and Warehousing: Used for loading and unloading goods efficiently.

Each of these applications benefits from the lift’s ability to provide reliable vertical movement while maintaining safety and ease of use. In public spaces, hydraulic platform lifts also help meet accessibility standards and promote inclusive design.

Factors to Consider When Choosing a Hydraulic Platform Lift

Selecting the appropriate hydraulic platform lift involves evaluating several important criteria to ensure it meets the specific needs of the environment. Key considerations include:

- Weight Capacity: Determine the maximum load the lift will need to handle.

- Platform Size: Ensure the platform can accommodate the intended users or goods.

- Travel Height: Measure the vertical distance the lift needs to cover.

- Installation Requirements: Assess space availability and structural compatibility.

- Usage Frequency: Choose a model designed to withstand the expected level of use.

Additionally, it’s important to consider the power source, safety features, and compliance with local building codes. Consulting with a qualified installer or supplier can help tailor the lift to your specific requirements and ensure long-term reliability.

Maintenance and Safety Best Practices

Regular maintenance is essential for the safe and efficient operation of hydraulic platform lifts. Establishing a routine inspection and servicing schedule can help prevent unexpected breakdowns and extend the life of the equipment. Recommended maintenance practices include:

- Fluid Checks: Monitor hydraulic fluid levels and quality to ensure proper function.

- Component Inspections: Examine cylinders, hoses, and seals for wear or leaks.

- Testing Safety Mechanisms: Regularly check emergency stop functions and safety gates.

- Cleaning: Keep the platform and surrounding area free of debris that could interfere with operation.

In terms of safety, operators should be properly trained, and lifts should only be used within specified capacity limits. Clear signage, user instructions, and emergency contact information should be accessible at all times to promote safe usage. By following these guidelines, users can enhance both performance and safety for everyone who interacts with the lift.

Conclusion: Enhancing Accessibility and Efficiency

Hydraulic platform lifts provide a practical solution for vertical mobility challenges across a wide range of environments. Whether installed in a commercial space, industrial facility, or residential property, these systems offer robust performance, safety, and adaptability. By understanding the key features, benefits, and maintenance requirements, users can make informed decisions that contribute to better accessibility, operational efficiency, and long-term value. For businesses and individuals alike, investing in a hydraulic platform lift is a step toward creating safer and more inclusive spaces.

Leave a Reply